Aries performed proof load testing and certification of 300 ton offshore crane using water bags and load cell.

Aries performed EMAG inspection of 5000 ton Offshore crane wire. Inspection was conducted on Main, Auxiliary, Wipe and Boom Host. .

Aries performed Hydro jetting, painting, aggregate application on Helideck to enhance friction as per CAP 437

Hydro jetting and painting performed on LNG Vessel in order to protect the main deck structures from corrosion and to improve the cosmetic appearance of the vessel

Coating failure rectification done on crude oil tanker vessel - Mechanical preparation, HP washing and Cosmetic application

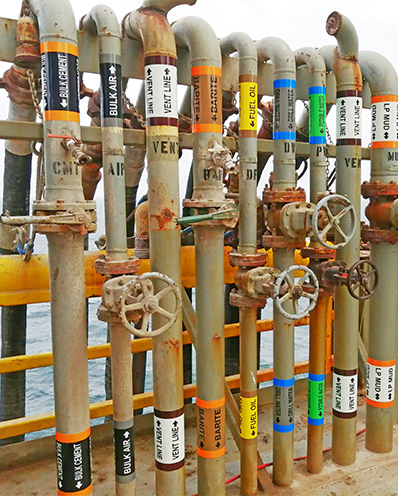

Aries marking services has been completed the pipe marking installation job onboard rigs at GOM offshore in USA.tion

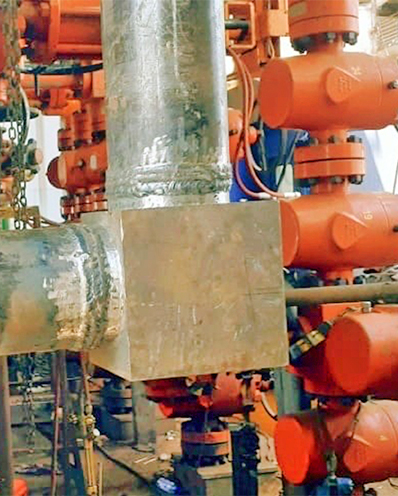

High Pressure lines repair/modification at Offshore-

Aries performed Choke & Kill lines, high pressure pipelines & manifold (10K, 15K) modification/installation works on-board Jack Up rigs at offshore.

Aries carried out GI duct fabrication and installation for onboard offshore rig - As per ABS guidelines

Aries Marine performed Helideck Inspection & Certification including Helideck Friction Testing, Perimeter Net Drop testing, Light Survey & Installation on Offshore Drilling Units & Platforms

1. Aries performed inspection on Rig leg structures and carried out Cropping & Renewal without effecting other Repair activities.

2. Aries performed the installation of steel cable ties to secure the drooped deluge line around the spherical storage tanks using rope access.

3. Aries performed the Hydro-jetting (WJ2) and Air less spray painting on cylindrical legs of Jack-up rig. The requirement of huge scaffolding erections and surrounding impact has been eliminated by using rope access.

4. Aries performed the protective coating on Splash zone of LNG jetty pile structure using rope access. Managed to remove the surface corrosion and applied the protective coating complying all the required specifications to prevent further corrosion. The whole process was achieved by adjusting the working time as per the low-high tide conditions and tireless effort of the committed rope access personnel.

Aries performed Oil country tubular goods (OCTG) Inspection for Drilling Rigs, Drill pipe manufactures & Drilling tools suppliers

Aries Performed Conventional/Advanced NDT techniques and Third-party inspection for Offshore windfarm Project. Scope of work were PAUT, UT, MT, PT, ACFM, Hardness testing, Radiography testing, Welding & Coating inspection.

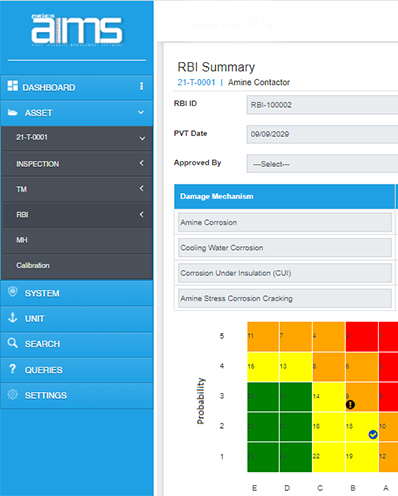

Aries performed Risk Based Inspection on Static Equipment, Process Piping, Pipelines and Storage Tanks at various process units of onshore and offshore facilities with the aid of in-house developed asset integrity management software (Aries AIMS).

Aries Performed LRUT & PEC to check the integrity of various assets including Pipe Lines in Petrochemical Plants & Refineries, Sphere Legs, Pressure Vessels, power industry, Marine & Offshore Platform, while in-service. Long Range Ultrasonic Testing (LRUT) is performed as a screening tool utilizing ultrasonic guided waves. Pulsed Eddy Current (PEC) is used to detect Corrosion under insulation (CUI) and corrosion under fireproofing (CUF)

Aries performed advanced NDT inspection of Heat Exchanger Tubes in Marine, Offshore, Oil & Gas and Nuclear sectors. Wide range of technology like Eddy current (ECT), Remote field eddy current (RFET), Magnetic field flux leakages (MFL), Internal Rotary inspection systems (IRIS) and Near filed testing (NFT) are used to detect defects like corrosion, longitudinal cracks, and circumferential cracks.

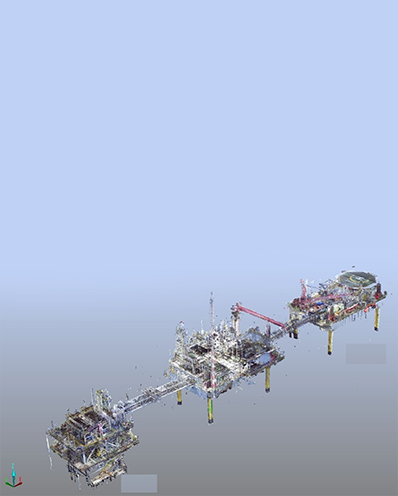

Aries has performed complete 3D laser scanning of 3.5km2 machinery tunnel facility in UAE and prepared as-built 3D model of whole facility together with asset tagging.

Aries performed engineering for Loadout and Sea Transportation of East Anglia Wind Farm Jackets of Scottish Power which were constructed in UAE and transported to UK.

Aries performed engineering for Loadout and Sea Transportation of East Anglia Wind Farm Jackets of Scottish Power which were constructed in UAE and transported to UK.

Aries completed the document review and marine warranty surveys for the loading, transportation and installation of 19 jackets and related boat landing platforms in SFNY, MRJN, HSBH, ZULF & BRRI fields as part of marine potential facilities long term agreement of Saudi Aramco

Aries scope include concept development, FEED, basic and detailed design of an offshore accommodation and training platform with jacket substructure in UAE waters

Aries has completed newbuild design of the self elevating unit "SEP Samrat" which functions as a pile installation and pile testing unit.

Aries completed the life extension studies for the drilling and production platforms in Nigeria Offshore. The engineering study included the structural assessment of as-is condition of the platforms and estimation of life based on fatigue analysis..

Aries provided engineering support for the upgrade of the rig for operating in deeper waters in Caspian Sea while retaining the VDL capacity.

Aries completed the detailed condition survey of MOPU Sapar Mayrat in Turkmenistan for assessment of structure, machinery and jacking system.

Aries performed the complete engineering for conversion of a tanker to "FSO Prem Pride" operated in India offshore for British Gas. The FSO unit had additional accommodation, offloading/bow loading systems, tandem mooring facilities along with storage facilities.

Aries did the complete engineering for the conversion of a Ro-Ro vessel to a cable laying ship, "CS Maram" operated by UAE entity. The converted ship had increase in hull dimensions, new cable tanks, new cable lay facilities etc..

Aries has completed newbuild design of the liftboatt "Aquarise III" which functions as an accommodation and offshore support unit.

Aries performed engineering for Loadout and Sea Transportation of the Shell’s Prelude FLNG turret modules weighing more than 10,000 MT, which were constructed in UAE and transported to South Korea.

Aries performed the complete engineering for conversion of the offshore supply vessel to a well stimulation vessel. The vessel was converted in UAE and were fitted with well stimulation equipment, tanks and associated systems.

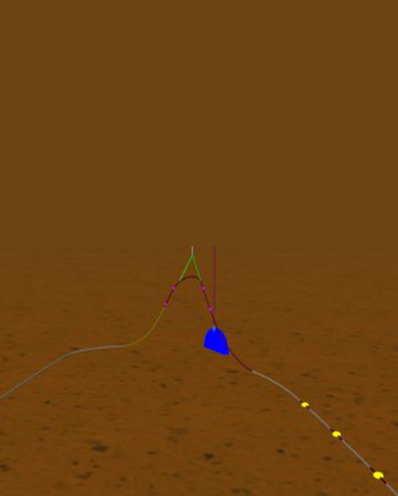

Aries did the engineering analysis and subsea simulation for the installation in multiple stages of umbilical cables for Marjan field of Saudi Aramco

Aries has performed engineering for more than 700 projects for ballast water treatment system retrofits which includes 3D scanning, feasibility studies, basic design, detail design, project management support, installation support and equipment supply for various clients around the globe.

Aries completed the life extension studies for the drilling and production platforms at Qatar offshore. The engineering study included the structural assessment of as-is condition of the platforms and estimation of life based on fatigue analysis..

Aries performed the review and approval of engineering drawings and calculations on behalf of owners for Adnoc’s “Rig Diyina” RIAP project in UAE.

Aries scope included the design for damage repair using grouting clamps and engineering assessment including geotechnical and ultimate strength analysis for a berthing dolphin at Adnoc LNG jetty site.

Aries acted as owners representative for supervision of newbuild construction of 3nos AHTS vessels constructed in China and India.